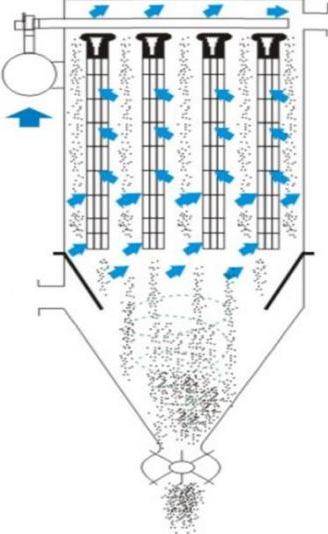

The filter bag cleaning device is installed on the upper part of the filter bag. When in operation, compressed air (7Kg/cm2) is sprayed in instantly and 5 to 7 times of secondary air is introduced to make the filter bag produce an expanding vibration effect. The expansion vibration effect and air backwashing action are used to achieve the effect of cleaning the filter bag.

During the cleaning action, the cleaning time of each group of filter bags is about 0.1 seconds. The dusty air enters from the bottom, and after primary separation by the separation plate, the coarse dust falls into the storage bucket below. Other dust is guided into the filter bag room and attached to the surface of the filter bag. The clean air after filtration passes through the filter bag and is discharged from the upper part. The dust attached to the surface of the filter bag is cleaned by jet backwashing. After shaking off, it is collected in the lower storage and discharged.

It is suitable for collecting various kinds of powders, such as the collectors of various production equipment in the chemical industry, food industry, pharmaceutical industry, and electronic industry. It can also effectively handle the dust collection of steel, non-ferrous metals, mining, various furnaces, ironmaking furnaces, melting furnaces, incinerators, various drying, mixing, and mixing exhaust dust collection.